A chemical air pump is a popular choice for transferring chemicals, acids and other hazardous fluids, thanks to their leak-free operation and diverse range of compatible materials. Before selecting a chemical pump, Global Pumps recommends assessing your liquids characteristics and ensuring the pump’s construction suits your application..

In this blog, we cover the different types of chemical air pumps and their common uses to support your selection process.

What is a chemical air pump?

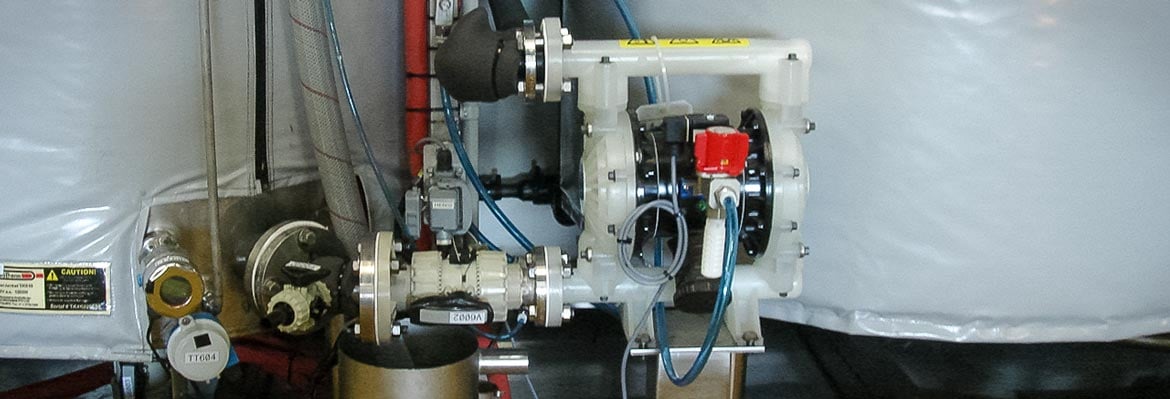

A chemical air pump is typically an air operated diaphragm pump, often called an AODD pump or pneumatic diaphragm pump). These positive displacement pumps are driven by compressed air rather than an electric motor, making them a safe choice for handling flammable, corrosive or volatile liquids.

Air operated diaphragm pumps designed for chemicals have two chambers, each containing a diaphragm, an inlet check valve, and an outlet check valve. Compressed air moves back and forth between the chambers, driving the diaphragms in a steady, reciprocating motion. As one chamber fills, the other empties – creating a consistent, pulsed pumping action without relying on electricity.

To learn more about how AODD pumps work, check out our quick explainer video here.

Why choose an air operated diaphragm pump for handling chemicals?

Chemical air pumps are ideal for transferring hazardous and aggressive fluids. Here’s why they’re trusted across industries:

- Safe and clean operation: Chemical air pumps have no motor, packing or seals - meaning minimal risk of leaks or emissions. The compressed air drive system makes them perfect for flammable or explosive environments where electrical pumps aren’t safe or practical.

- Dry running capabilities: An air operated diaphragm pump can run dry or against a closed discharge without damage. This makes them ideal for applications where pumps are left running intermittently or unattended.

- Self-priming: AOD pumps are self-priming, requiring no manual priming. This is especially useful in applications where the suction conditions are difficult, such as pumping from chemical drums or containers.

- Flexible performance: These pumps are versatile in performance, and are capable of meeting exact flow rate or pressure requirements. With a wide range of materials of construction available, chemical air pumps are adaptable to virtually any fluid type.

Many AODD pumps also come with ATEX certification and chemical-resistant components to ensure operational safety and site compliance.

Selecting materials for chemical air pumps

Choosing the right construction material is essential for chemical compatibility and long-term durability. We recommend using Global Pumps’ chemical compatibility table to determine the best fit for your fluid.

Common materials of construction available for chemical air pumps include:

- Polypropylene – wide range of chemical compatibility, general purpose and resistant to high temperatures

- Conductive polypropylene – electrically conductive polypropylene, for explosive environments

- PVDF – polyvinylidene fluoride or polyvinylidene difluoride, is a highly non-reactive thermoplastic fluoropolymer produced by the polymerisation of vinylidene difluoride

- Acetal – compatible with a variety of solvent applications, and resistant to abrasive media. This option is suitable for ATEX requirements

- Aluminium – commonly used in general purpose applications, solvent-based coatings and inks and resistant only to mild chemicals

- Cast iron – highly abrasive resistant, commonly found in paper, waste water industry and mining

- Stainless steel 316 – resistant to a wide range of acids, bases, solvents. Handles hydrocarbons and has good resistance to abrasive media as well.

Common applications for chemical air pumps

Air operated double diaphragm pumps designed for chemicals are widely used in:

- Acids and chemical transfer

- Oils and hydrocarbon pumping

- Drum and container transfer

- Chemical Dosing

- Acid bath circulation

- Flammable liquid transfer

- CIP chemical handling

- Sample collection

- Drum cleaning

- General chemical fluid transfer.

Chemical air pumps are also relied upon in mining, manufacturing, and industrial operations that involve hazardous or corrosive fluids

Want to learn more about chemical air pumps?

If you’re looking for a safe, reliable chemical air pump, speak to the experts at Global Pumps. We’ve helped clients across the chemical, mining and manufacturing sectors find the right pump tailored to their application. Contact our team today to discuss your requirements!