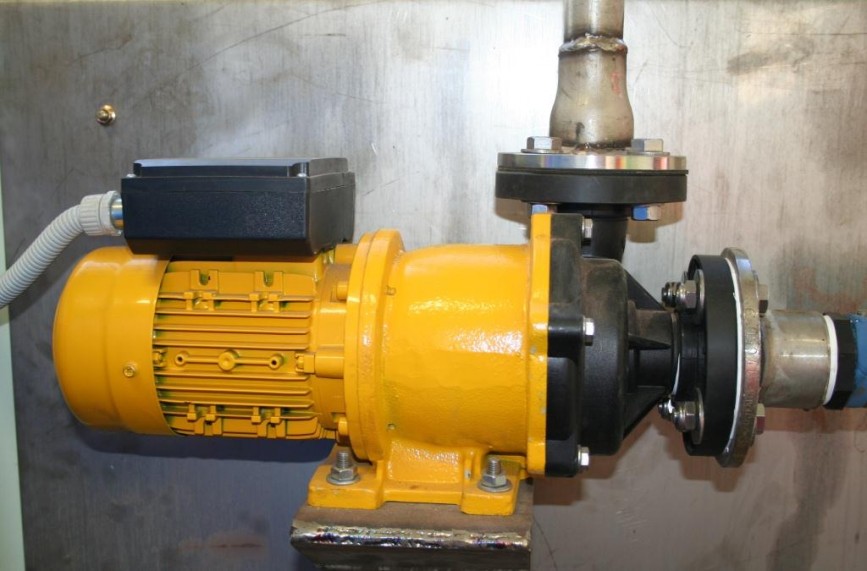

TB Series High Temperature Magnetic Pumps

The TB Series is a robust high temperature magnetic drive pump built for corrosive and hazardous liquids in demanding industrial and chemical environments. With a ductile iron casing and bonded PTFE or PFA lining, it delivers exceptional corrosion resistance, durability, and efficiency.

This model performs reliably under extreme process conditions and can be configured with stainless steel casing for pumping of flammable liquids or liquids that don’t require a full PTFE lined pump

Specifications:

- Flow rates up to 300 m3/hr

- Heads up to 100 m

- Specific gravity up to 2.5

- Fluid temperatures range from -70 °C to 121 °C

- Pressures up to 20.7 bar (300 psi)

- Open impeller for improved NPSHr and efficiency

For a smaller installations, the TB Series, the Techniflo U-Mag Series Centrifugal Pump offers the exact same materials of construction but is designed for smaller and more refined applications. Features of the U-Mag series include:

- Flow rates to 102 m3/hr

- Heads to 50 m

- Low NPSH for efficient operation