FAQs

How does an AOD Pump work?

An air operated diaphragm pump uses compressed air to create a reciprocating motion in two flexible diaphragms. This motion draws in and expels fluid in alternating cycles. Read our detailed article on air operated diaphragm pump working principle.

What are the key features of an AODD pump?

AODD pumps offer a range of benefits:

- Leak-free design – no piston rods through the pressure boundary

- Self-priming from a dry start

- Dry-run capable – no damage if run without fluid

- Variable flow and pressure – up to 870 kPa, adjustable via air supply

- Submersible operation – suitable for flooded suction or fully submerged installs

- Low maintenance – no gland packing or sliding/rotating parts

- Portable and lightweight – easy to move between applications

- Available in various materials – both metallic and non-metallic diaphragm pumps to suit the fluid type

Where can air operated diaphragm pumps be used?

AODD pumps are suitable for a wide range of applications:

- Chemical processing

- Paint, ink, and coating transfer

- Food and beverage (including hygienic and CIP applications)

- Mining and dewatering

- Drum and container transfer

- Flammable or hazardous liquid handling

How do I read an air operated diaphragm pump curve?

We’ve created a helpful video and blog article explaining how to read and interpret AOD pump performance curves. Watch it here.

We also have a blog article on how to read an air operated diaphragm pump performance curve.

How many sizes and materials are available?

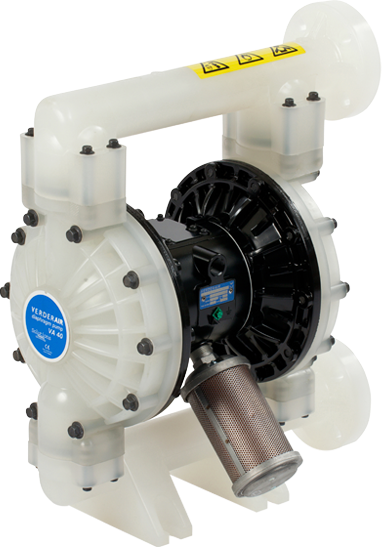

We stock seven sizes across a range of plastic and metal diaphragm pumps, including:

- Polypropylene, conductive polypropylene, PVDF, and acetal (non-metallic)

- Aluminium, cast iron, and stainless steel 316 (metallic)

This ensures there’s a suitable material for nearly every fluid type and operating condition.

How do I choose the right AOD pump?

When selecting an air operated diaphragm pump, consider:

- Fluid type: Is it abrasive, corrosive, or hazardous?

- Viscosity: Thicker fluids require larger or more robust pumps

- Flow rate: Litres per minute (L/min) or per hour (L/hr)

- Pressure requirements: Refer to a pump curve for guidance

- Temperature: Ensure the materials can handle the fluid temperature

Need help? Download our AODD Cheat Sheet or speak to one of our specialists for tailored advice. You may also find the answers to your questions in our helpful blogs: types of pumps or diaphragm pump flow rate calculations.

What fluids can AODD pumps transfer?

Almost any kind - including clean liquids, slurries, corrosive chemicals and viscous media. As long as the fluid is compatible with the pump’s construction material, pneumatic diaphragm pumps will reliably transfer it. For highly viscous fluids, larger port sizes or reduced piping resistance may be required.

Are there specific considerations for plastic diaphragm pumps?

Yes. Plastic diaphragm pumps can deform slightly over time, so it’s important to:

- Regularly check bolt torque to avoid leaks

- Ensure chemical compatibility between the fluid and plastic material

- Inspect pump casing for compression or shape changes

Why do air operated diaphragm pumps freeze?

Although Verderair pumps are anti-freeze, we have created an article explaining why air operated diaphragm pumps freeze.

What maintenance is required?

AOD pumps are relatively low-maintenance. Key areas to monitor:

- Air quality - Install in-line filters to remove moisture and debris.

- Elastomers (diaphragms) - Inspect and replace periodically.

- Fluid pathways – Check for clogs at the inlet and outlet.

- Torque settings – Especially on plastic models, re-check regularly.

What is the purchase process?

Our Global Pumps team will assess your application, fluid properties, and environment to recommend the best AODD pump solution. We’ll provide a detailed quote with lead times, pricing and compatibility considerations.

Where do you deliver and how long does shipping take?

We ship our air operated diaphragm pumps Australia-wide. Below is a general guide to delivery times for major cities, but our team can confirm specific lead times for your location or project.

| Locations |

Shipping Time Range |

| Melbourne |

1-2 Days |

| Sydney |

2-3 Days |

| Brisbane |

2-4 Days |

| Perth |

2-4 Days |

| Adelaide |

1 Day |

| Kalgoorlie |

3-5 Days |

| Mt Isa |

3-5 Days |