Understanding how a diaphragm pump works can help you choose the right equipment for your application - especially when handling viscous, abrasive, or chemically aggressive fluids. One of the most popular and versatile options is the air operated diaphragm pump (AODD pump), widely used across industries for its safety, efficiency, and reliability.

This article breaks down the diaphragm pump mechanism, how it operates, and where it’s commonly used.

What is an air operated diaphragm pump?

An air operated diaphragm pump - also known as a pneumatic diaphragm pump - is a type of positive displacement pump. Instead of using electricity or rotating parts, it relies on compressed air to drive the pumping action.

This design makes it ideal for hazardous or remote environments where electrical components might pose a risk or be unavailable. These pumps are often used in mining, chemical transfer, food processing, and wastewater applications, where robust and consistent fluid handling is essential.

Pneumatic diaphragm pump: How it works

So, how does a pneumatic diaphragm pump work?

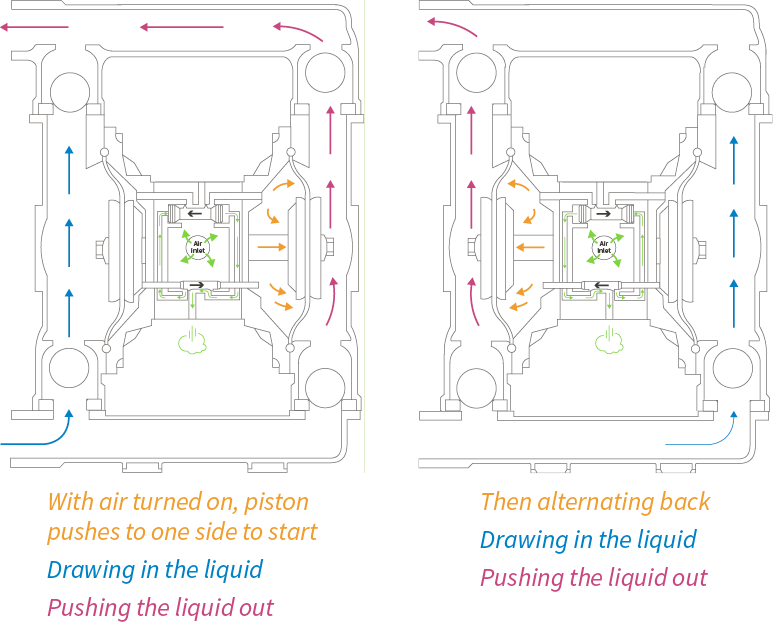

At the heart of the design is a set of two flexible diaphragms connected by a shaft, with each diaphragm housed in its own pumping chamber. The air operated diaphragm pump working principle can be explained in a few key steps:

- Compressed air enters the pump and moves into the air valve (also known as the air motor).

- As the diaphragm moves, it displaces liquid out of that chamber.

- At the same time, the opposite diaphragm is pulled inward, creating suction that draws fluid into the second chamber.

- One-way check valves (often ball or flap valves) control the direction of flow—fluid enters one side while being discharged from the other.

- The air valve shifts, and the process reverses—this back-and-forth motion continues rapidly, with some pumps operating at up to 400 cycles per minute.

This alternating motion is what defines the air operated double diaphragm pump design and ensures continuous, smooth pumping.

Key features of the diaphragm pump mechanism

The diaphragm pump mechanism offers several practical benefits:

- Self-priming and capable of running dry without damage

- Safe for explosive environments, as no electricity is required

- Handles solids and slurries with ease

- Gentle pumping action, ideal for shear-sensitive fluids

- Simple maintenance, with minimal moving parts

With fewer wear components than in mechanically driven pumps, AOD pumps are cost-effective and dependable, even in harsh conditions.

Choosing the right air operated diaphragm pump

Selecting the right diaphragm pump depends on your application. Factors such as fluid type, viscosity, chemical compatibility, temperature, and required flow rate all come into play. By understanding how a diaphragm pump works and the underlying air operated diaphragm pump mechanism, you’ll be better equipped to make an informed decision.

If you're not sure whether a pneumatic diaphragm pump is right for your setup, our team can help. Contact us today and one of our experienced technicians will be happy to answer any of your questions.