In our last blog we talked about the importance of the suction line and how it can affect your system. In this post we will go over different recommendations from various pump manufacturers as to what they recommend for their type of pump.

Centrifugal pump suction recommendations

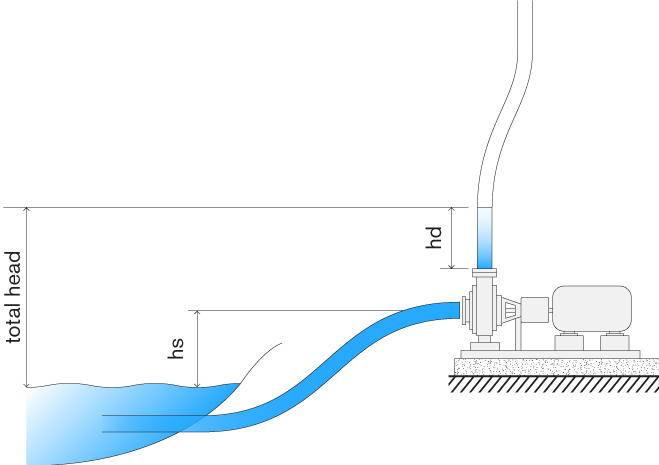

SUCTION PIPING – Suction pipe should be direct and as short as possible. It should be at least one size larger than suction inlet tapping and should have a minimum of elbows and fittings (5 to 6 pipe diameters of straight pipe before inlet is recommended).

The piping should be laid out so that it slopes upward to pump without dips or high points so that air pockets are eliminated.

The highest point in the suction piping should be the pump inlet except where liquid flows to the pump inlet under pressure.

The suction pipe must be tight and free of air leaks or the pump will not operate properly.

Click here for more information on Centrifugal pumps.

Magnetic drive pump suction recommendations

Reducers, if used, should be eccentric and installed at the pump suction flange with eccentric side on the bottom. The length of the suction pipe should be kept to a minimum. Suction piping should be installed with a gradual rise to the pump to eliminate any air pockets. The diameter of the suction pipe should always be as large or larger than the pump suction.

Elbows or fittings should be avoided at suction flange. Allow at least 10 pipe diameters in length for straight run into the pump.

If a valve is used in the suction, use only full flow valves. These valves should be for shut-off only when the pump is not running, not for throttling or controlling flow. A valve designed for flow control should be installed in the discharge. This valve line can be used for throttling.

Suction strainers, when used, must have a net free area of at least three times the suction pipe area.

An isolation valve should be installed in the suction line at least two pipe diameters from the suction to permit closing of the line for pump inspection and maintenance.

Click here for more information on Magnetic drive pumps.

Air operated diaphragm pump suction recommendations

The suction pipe size should be at least the equivalent or larger than the diameter size of the suction inlet on your pump. The suction hose must be non-collapsible, reinforced type as these pumps are capable of pulling a high vacuum.

It is critical that all fittings and connections are airtight, or a reduction or loss of pump suction capability will result.

Click here for more information on Air operated diaphragm pumps.

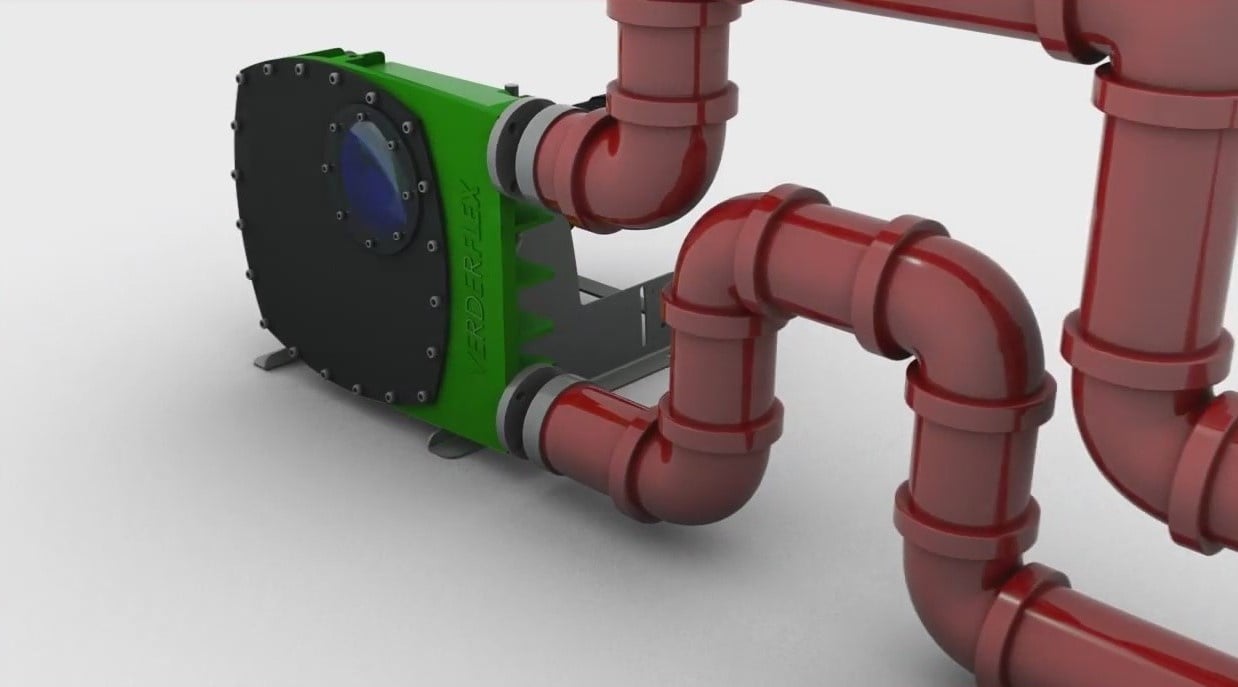

Peristaltic hose pump suction recommendations

Specifying supports and flange connections

When planning pipe runs, take every possible operating condition into account:

- Cold/warm medium

- Empty/full

- Unpressurised/pressurised

- Positional change of the flanges

Specifying nominal diameters

Keep the flow resistance in the pipes as low as possible. Pipe work immediately connected to both inlet and outlet port of the pump should be straight runs for at least one metre (1m).

Ensure that nominal pipe diameter is at least 1.5 times nominal pump-hose diameter to reduce pulsation.

Specifying pipe lengths

- Keep pipe work as short and direct as possible.

- To allow easy access when changing hoses, include a short, removable section adjacent to the port flanges.

Optimising cross-section of pipe work

- Avoid bending radii of less than 10r (r - the radii of nominal piping)

- Avoid abrupt changes of cross-section along the piping.

Click her for more information on Peristaltic hose pumps.

Providing safety and control devices

Making provisions for isolating and shutting off pipes

- For maintenance and repair work. Provide shut-off valves in the suction and discharge lines.

Allowing safe removal of product

- Include drainage taps in suction and discharge lines at the lowest point.

These are just a few extracts from manufacturers' recommendations for their pumps. It is best to read the manufacturers manual and/or contact a pump expert for technical advice when installing your pump.

Looking for Advice?

Get expert advice from Global Pumps, Australia's most trusted industrial pump supplier. Contact one of our friendly pump experts today!