A low-shear pump is designed to transfer fluids without causing significant damage to the physical properties of the fluid. This type of pump works by using a gentle, consistent pressure to move fluids through the system.

How does a low-shear pump work?

The basic design of a low-shear pump involves rotating components, such as impellers or rotors, which move the fluid through the pump. These components are engineered to minimise turbulence and shear forces that can damage delicate fluids such as emulsions, polymers, flocculants, or shear-sensitive liquids like milk and cream.

Low-shear pumps operate at lower speeds and with wider passages than high-shear pumps, which helps to reduce shear forces and maintain the integrity of the fluid being pumped. They may also incorporate specialized features such as gentle start-up and shutdown procedures, variable speed controls, and other measures to minimise shear and turbulence.

Why choose a low-shear pump?

There are several reasons why one might choose a low-shear pump over a high-shear pump. Some common reasons include:

- Preservation of fluid properties: Low-shear pumps are ideal for transferring delicate fluids such as milk that can be damaged by excessive turbulence and shear forces. By using a low-shear pump, the fluid properties can be preserved, resulting in higher quality final products.

- Consistency: Low-shear pumps provide a consistent flow rate, which is essential in applications where accuracy and precision are critical.

- Versatility: Low-shear pumps can handle a wide range of fluid viscosities and flow rates, making them a versatile choice for a variety of applications.

- Cost-effective: Low-shear pumps are often more cost-effective than high-shear pumps due to their simple design and lower maintenance requirements.

Some examples of low-shear pumps

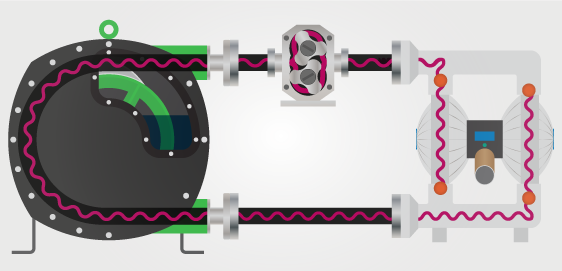

The low shear pump market is diverse, with different models designed for different applications. The following are some examples of low shear pumps:

-

Peristaltic pumps: These pumps use rollers to compress a flexible tube, creating a gentle, low shear pumping action. They are often used in the food, pharmaceutical, biotech and mining industries.

-

Lobe pumps: the material is moved through the pump via two rotating lobes, resulting in low shear pumping. They are commonly used in the food and beverage industry for handling delicate products such as dairy, chocolate, and fruit purees.

-

Diaphragm pumps: Diaphragm pumps use a flexible diaphragm to move material through the pump. Chemical industries often use them for pumping polymers and coatings that are shear-sensitive.

-

Progressing cavity pumps: These pumps use a helical rotor and stator to move material through the pump, resulting in a low shear pumping action. Food and beverage industries commonly use them to handle materials with viscous and shear-sensitive properties, such as tomato paste, yogurt, and fruit juice concentrates.

Overall, a low-shear pump is a reliable and efficient option for transferring fluids that require gentle handling to maintain their integrity. For that reason, in many industries where sensitive materials need to be pumped without degrading or causing damage, it is a valuable tool.

At Global Pumps, we specialise in providing low shear pumps for clients across Australia. We have a team of knowledgeable staff who are dedicated to finding the perfect solution for all your pumping needs. Get in touch with our Global Pumps team today and find out how we can help.