Put some clear and concise content in here. Keep your reader in mind. What are they trying to do? What are they hoping to learn? Why are they reading this? Help them out and use the tone and voice of your organization.

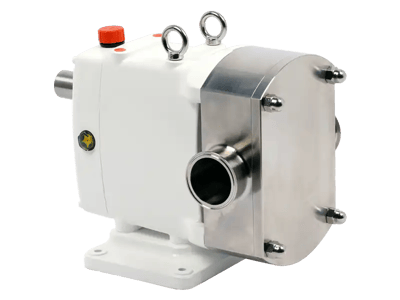

Lobe pumps are a versatile positive displacement pump solution used across hygienic, industrial and process-driven applications. Known for gentle product handling, consistent flow and excellent cleanability, rotary lobe pumps are ideal where product integrity and sanitation are critical. Global Pumps supplies a comprehensive range of rotary lobe pumps, including twin and helical lobe pumps, manufactured from high-quality stainless steel for reliable performance in both sanitary and industrial environments.

Key features of our lobe pumps range include:

No working principle found

A lobe pump working principle is based on positive displacement using rotating lobes within a precision-machined casing. As the lobes rotate, they create expanding cavities on the inlet side of the pump. Fluid enters these cavities and becomes trapped between the lobes and the pump casing.

The fluid is carried around the outside of the lobes without direct contact between rotating elements. As the lobes continue to turn, the cavities reduce in size on the discharge side, pushing the fluid out of the pump at a consistent and controlled rate.

Key characteristics of the rotary lobe pump working principle include:

Helical lobe pumps use a similar principle but incorporate twisted lobes to further reduce pulsation and improve flow smoothness, making them ideal for highly viscous or sensitive fluids.

Thanks to their hygienic construction and flexible performance, lobe pumps are used across a wide range of industries and processes, including:

Their ability to handle viscous, abrasive and shear-sensitive products makes lobe pumps a preferred solution in both sanitary and industrial applications.

No downloads available

Are lobe pumps suitable for sanitary applications?

Yes. Sanitary and hygienic lobe pumps are specifically designed for applications requiring strict hygiene standards. Stainless steel construction, smooth internal surfaces and CIP compatibility make them ideal for food-grade and pharmaceutical use.

Can lobe pumps handle abrasive or viscous fluids?

Lobe pumps are well suited to viscous, abrasive and solids-containing fluids. Their non-contacting rotors minimise wear while maintaining consistent flow, even with challenging media.

Where do you deliver and what is your estimated shipping times?

Global Pumps provide speedy deliver straight to your site, no matter where you are located in Australia.

| Locations | Shipping time range |

| Melbourne | 1-2 days |

| Sydney | 2-3 days |

| Brisbane | 2-4 days |

| Perth | 2-4 days |

| Adelaide | 1 day |

| Kalgoorlie | 3-5 days |

| Mt Isa | 3-5 days |

Global Pumps offers a wide range of sanitary and industrial lobe pumps suitable for fluid transfer, dosing and processing across multiple industries. These pumps are designed to meet strict hygiene standards while providing the strength and reliability required for continuous operation.

Our hygienic lobe pumps are manufactured using stainless steel casings and rotors, sanitary mechanical seals and smooth internal surfaces. This construction supports CIP (Clean-in-Place) processes and ensures compliance with food, beverage and pharmaceutical regulations.

Lobe pumps are ideal for handling:

Food-grade and sanitary lobe pumps are designed to safely transfer products without contamination or product degradation. Their non-contacting lobes gently move fluid through the pump chamber, preserving texture, structure and quality.

These stainless steel lobe pumps are commonly used in:

All sanitary lobe pumps supplied by Global Pumps are constructed from food-grade materials and engineered to meet industry hygiene standards.

The ZW series rotary lobe pumps are designed for applications involving liquids with small soft solids, such as grape skins, seeds and stems. Featuring rubber heli-lobe rotors, these pumps provide gentle handling while preventing product damage and maintaining high efficiency. They are well suited to wine, juice, pomace and similar fluid transfer applications where product integrity is critical.

The ZL series rotary lobe pumps offer a highly versatile solution for hygienic pumping applications. With a wide range of rotor configurations and optional features, this series can be tailored to suit varying product characteristics and process requirements. This flexibility ensures efficient, reliable performance across a broad range of sanitary and food-grade applications.

Put some clear and concise content in here. Keep your reader in mind. What are they trying to do? What are they hoping to learn? Why are they reading this? Help them out and use the tone and voice of your organization.

Put some clear and concise content in here. Keep your reader in mind. What are they trying to do? What are they hoping to learn? Why are they reading this? Help them out and use the tone and voice of your organization.

Put some clear and concise content in here. Keep your reader in mind. What are they trying to do? What are they hoping to learn? Why are they reading this? Help them out and use the tone and voice of your organization.

If you need some guidance on how to select the right pump then you’re not alone! There’s such a wide range of pumps in Australia, from centrifugal pumps to hose pumps to diaphragm pumps. The options available to you can make it a difficult choice, so we’ve created this special guide to help step you through the process of selecting the ideal pump for your requirements.

Looking for pump stations?

Visit Global Water

Head Office

12 Selgar Avenue Tonsley

South Australia 5042