Learn more about product range for the food and beverage industry:

https://www.globalpumps.com.au/product-by-industry/food-beverage

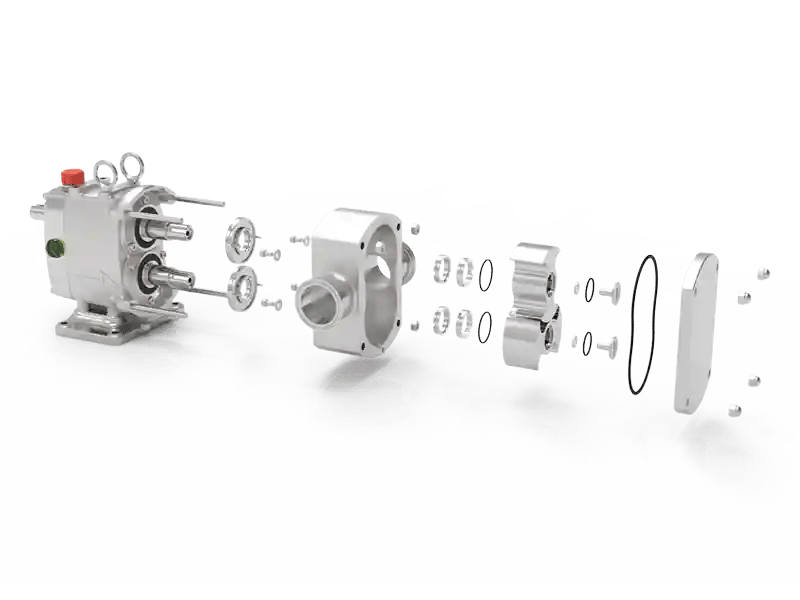

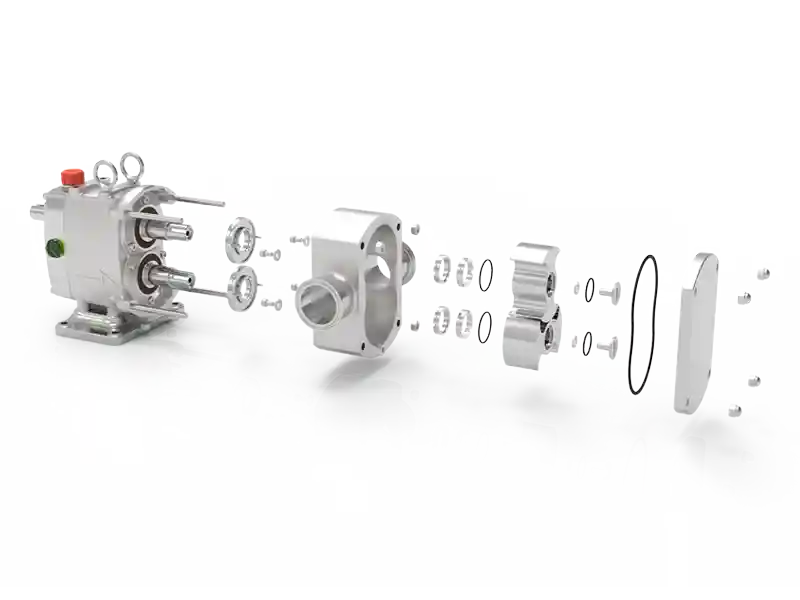

Packo Rotary Lobe Pumps ZL

The Packo rotary lobe pumps stand at the forefront of innovation. This versatile series offers a wide range of rotor choices and options, making it adaptable to virtually any hygienic pumping application. This, in turn, guarantees the highest levels of efficiency and effectiveness in the pumping process.

Features of the Global Pumps range of Packo rotary lobe pumps include:

No working principle found

This lobe pump operates similarly to standard models but stands out with highly polished internals. These polished surfaces enable easy cleaning, crucial for preventing bacterial contamination in sensitive applications.

Additionally, lobe pumps excel in gentle product handling, making them ideal for shear-sensitive materials. They boast strong self-priming capabilities, ensuring efficient start-up, and are well-suited for applications requiring controlled flow rates.

The combination of these features positions lobe pumps as a reliable choice for hygienic and efficient fluid transfer.

Packo rotary lobe series ZL pumps are suitable in the following applications:

They are the ideal solution for gentle pumping of low to high viscous liquids.

No downloads available

Can you provide the complete turnkey package?

Our engineering team is well-equipped to assist in designing and sourcing the majority of additional components required for your project.

What ensures the hygiene of these pumps?

The cleanliness of a pump is linked to the surface finish of its internal components. The more finely polished these internals are, the fewer hiding places there are for bacteria.

What standards do Packo products adhere to?

Packo products have EHEDG, 3-A, and FDA approvals.

What is the maximum head of a Packo ZL Lobe Pumps?

Our ZL Range of Lobe pumps can provide up to 20Bar of discharge pressure

What is the maximum flow a Packo ZL Lobe Pump can deliver?

Our ZL range of Lobe pumps can deliver up to 100m3/hr

Can I request different connections?

Certainly, we can provide a variety of flanges and connections.

I'm operating in a hazardous environment; can this pump be used?

Yes, we can supply an Ex-rated motor for your application.

What applications are the Packo rotary lobe pumps series ZL used in?

They are the ideal solution for gentle pumping of low to high viscous liquids. For example, hygienic applications in dairies, breweries, the pharma and cosmetics industries and bakeries, as well as for pumping liqueurs, detergents, shampoos, gels, etc.

Where do you deliver and what is your estimated shipping times?

Global Pumps provide speedy delivery straight to your site, no matter where you are located in Australia.

| Locations | Shipping time range |

| Melbourne | 1-2 days |

| Sydney | 2-3 days |

| Brisbane | 2-4 days |

| Perth | 2-4 days |

| Adelaide | 1 day |

| Kalgoorlie | 3-5 days |

| Mt Isa | 3-5 days |

Global Pumps offers a wide range of Packo rotary lobe pumps for a variety of applications.

The Packo ZL series rotary lobe pumps are meticulously engineered for diverse hygienic applications, including dairies, breweries, the pharmaceutical and cosmetics industries, bakeries, and the pumping of liquids such as liqueurs, detergents, shampoos, and gels. They represent the perfect solution for the gentle transfer of liquids with a wide viscosity range, from low to high.

Benefits:

CLEANER

Certified to EC1935/2004, EHEDG and 3A versions available

- wetted surfaces with Ra < 0.6 µm

- wetted parts in SS316L

SHORTER DOWNTIMES / HIGHER FLEXIBILITY

Technical specifications:

| Materials wetted parts | Stainless steel 316L |

| Seal configuration | sSingle, flushed, double mechanical seal, O-ring seal, triple lipseal |

| Available material O-ring | EPDM, FKM, FFKM |

| Connections | Sanitary and industrial fittings, rectangular inlet available |

| Mounting position | Horizontal and vertical |

| Surface finish | Food quality, internal welds hand polished to 0.6 μm |

Not sure? Check out the range of pumps or contact us if you need any help.

Learn more about product range for the food and beverage industry:

https://www.globalpumps.com.au/product-by-industry/food-beverage

If you need some guidance on how to select the right pump then you’re not alone! There’s such a wide range of pumps in Australia, from centrifugal pumps to hose pumps to diaphragm pumps. The options available to you can make it a difficult choice, so we’ve created this special guide to help step you through the process of selecting the ideal pump for your requirements.

Looking for pump stations?

Visit Global Water

Head Office

12 Selgar Avenue Tonsley

South Australia 5042