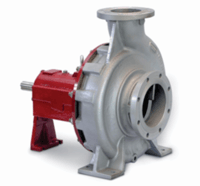

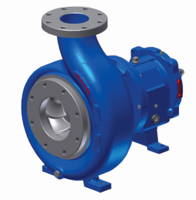

TORO ANSI and ISO centrifugal process pumps are the robust solution for heavy duty pumping applications in a wide range of industries including Chemical, Petrochemical and Primary Metals. The TORO pumps use a straightforward design that incorporates durable materials and cutting-edge mechanical seal designs to provide a cost effective solution to sites affected by unreliable pumps. To discover how you can use TORO pumps to enhance your operations download the brochure below and contact our friendly experts today!

Features:

- Constructed from durable metals

- Flows up to 1000 m3/hr

- Heads up to 150 metres

- Handles liquid temperatures from -210℃ to 260℃

- Working pressures up to 2550 kPA

- Advanced mechanical seal design adapted for tough applications

QUALITY GUARANTEED

Quality control, including identification and traceability of components from foundry to end-user, ensure that parts consistently perform beyond industry expectations.

No matter what you require for your specific project, talk to our pump experts for comprehensive advice today.

Download the TORO Brochure