Transferring hazardous substances between sites, by truck, is essential and can be extremely dangerous if done unsafely. The cargo itself is hazardous and very valuable. In order to ensure the safety of the driver and staff on site, the transfer of the liquid from the tanker to a holding tank/IBC is critical. A leakage of the highly aggressive chemicals may cause damage to the site, staff, equipment and the surroundings.

The following are commonly found in tankers:

Different tanker loads may need different pump materials to withstand the arduous, corrosive and aggressive properties of the load. It would be beneficial for the pump to be capable of running dry. Generally, pumps are run until the operator hears cavitation prior to switching off. When offloading in cold weather, the viscosity of a substance can increases rapidly. And as you handle more viscous media the unloading pump discharge pressure may not be high enough to overcome the elevation head required to pump into the storage tank.

In traditional settings, multiple different pumps have been utilised but have failed. Pumps commonly selected for tanker offloading include:

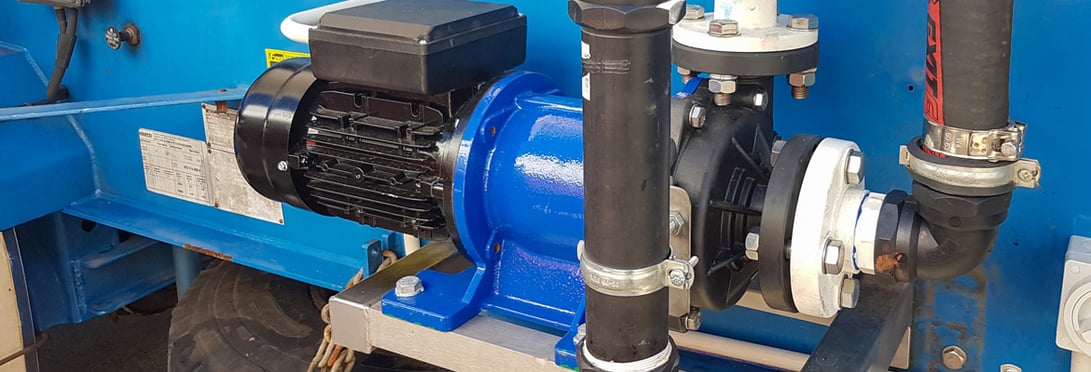

Global Pumps suggest a Techniflo magnetic drive pump. These pumps do not use mechanical seals and are 100% leak free. Every mag-drive pump is designed to have as few parts as possible to ensure robust operation with an emphasis on quality and reliability. The range of magnetic drive pumps from Techniflo offer engineered plastics and high-grade ceramics meaning there are a corrosion resistant pump. Besides their construction, they also offer reduced downtime, easy maintenance and operator confidence.

Global Pumps are committed to providing long-term results and high performing pumping systems. Depending on the chemical being pumped, we have a wide range of pumps that are appropriate for all applications. For more information on the Techniflo range of chemical magnetic drive pumps, or to chat to a Global Pumps team member about tank offloading, give us a call.

If you need some guidance on how to select the right pump then you’re not alone! There’s such a wide range of pumps in Australia, from centrifugal pumps to hose pumps to diaphragm pumps. The options available to you can make it a difficult choice, so we’ve created this special guide to help step you through the process of selecting the ideal pump for your requirements.

Looking for pump stations?

Visit Global Water

Head Office

12 Selgar Avenue Tonsley

South Australia 5042