PRODUCT INFORMATION

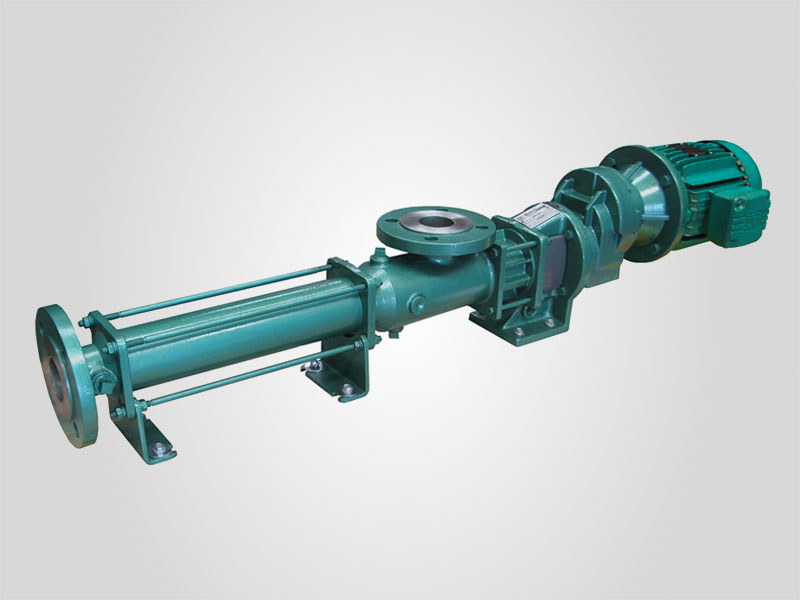

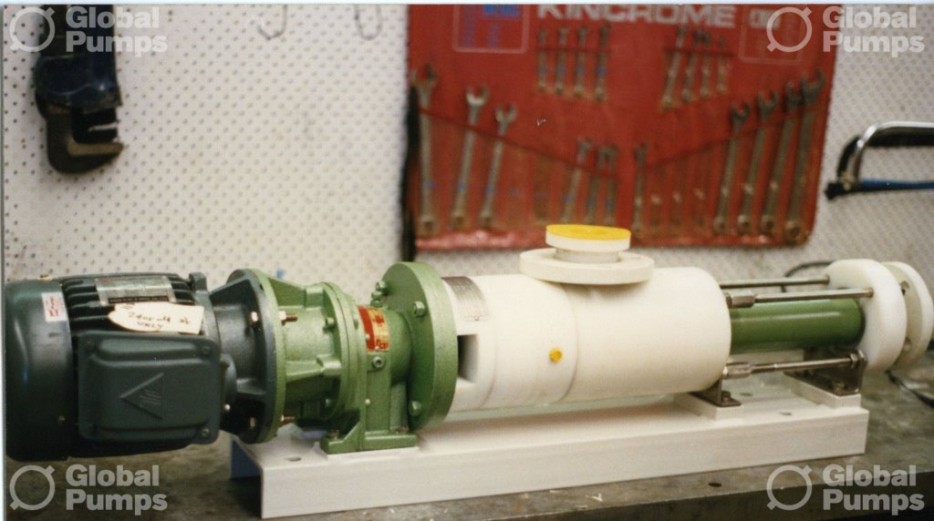

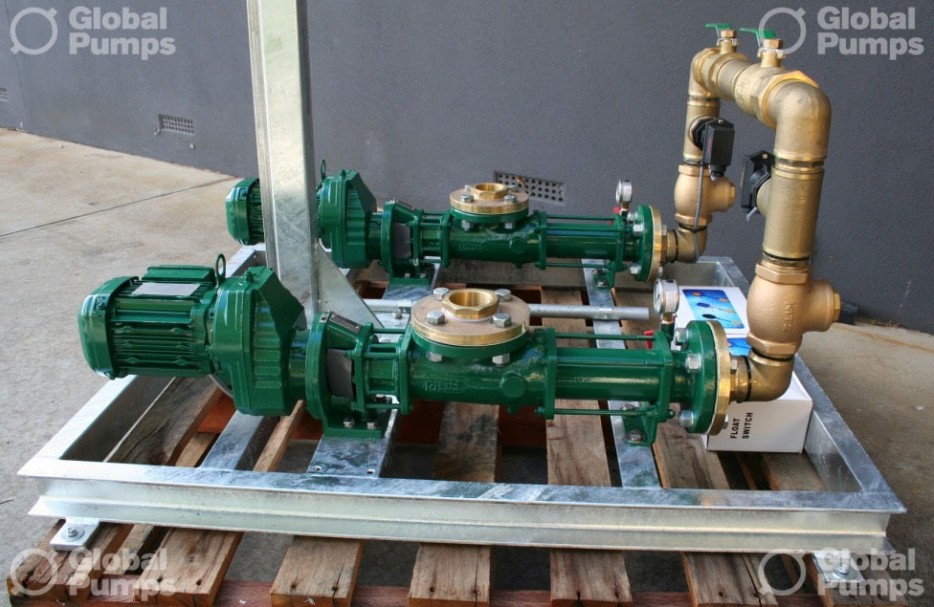

As a helical rotor pump manufacturer, Global Pumps offers a variety of pumps with the following features:

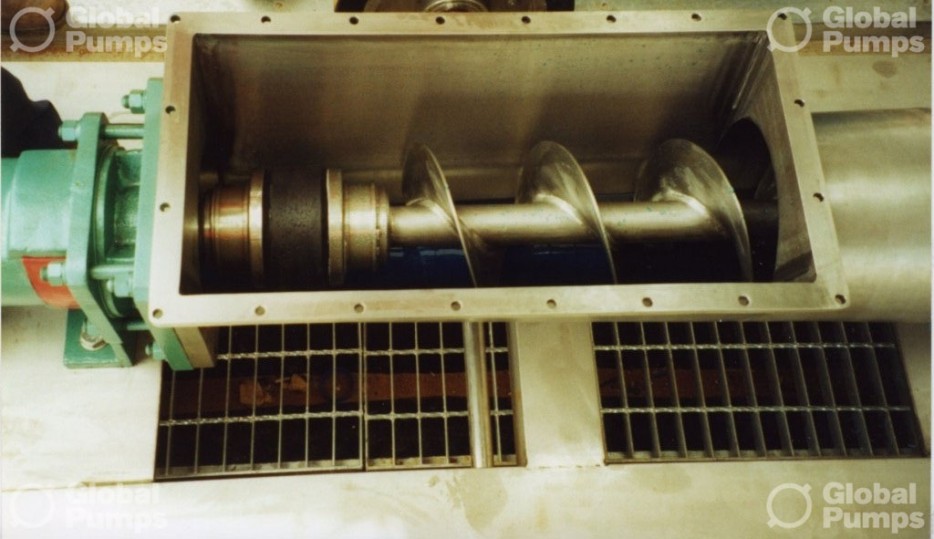

The helical rotor pump offers a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. They offer a smarter shaft sealing, tough bearings, improved pump housing and tapered entry stator. The helical rotor pump offers operators the following benefits: self-priming, non-clogging, low NPSH requirement, low internal velocity, silent running and separate bearing housing.

They also offer reduced thrust loads on bearing and universal joins, ensuring an increasing service life. As well as smooth and even performance, reduced vibration, turbulence, shear rates and pulsation, lower sliding velocity, lengthy pitch and lengthy geometry.

The range of helical rotor pumps offer the following for operators:

- viscosity up to 30,000 cst

- can handle temperatures up to 150 °C

- solid handling up to 7%

- discharge pressure up to 48 bar (341 PSI)

- capacity: up to 345 m3/hr

- head up to 500 m3/hr

- available in a variety of constructions including cast iron, with rotating parts in alloy steel, tool steel, SS 304 and SS 316

Global Pumps also offers other types of pumps such as peristaltic hose pumps and submersible pumps.