FAQs

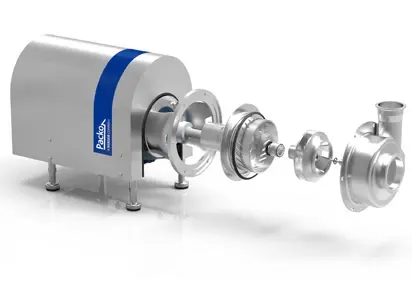

1. What industries are the Packo pumps suitable for?

The Packo range is ideal for food and beverage, cosmetics, pharmaceuticals, and chemical industries, where precise mixing, homogenisation, and dispersing are required.

2. Can these pumps handle high-viscosity products?

Yes. The SFP2, SFP3, and CM can process a wide range of viscosities, making them suitable for sauces, creams, lotions, emulsions, and high-viscosity suspensions.

3. How hygienic are these pumps?

All Packo pumps feature electropolished stainless steel surfaces, smooth construction with no bacteria traps, and easy-to-clean clearances around seals, ensuring compliance with strict hygiene standards.

4. Are the pumps energy efficient and quiet?

Yes. Packo pumps are designed for high efficiency, which saves energy, and operate very quietly, making them ideal for busy production environments.

5. What types of mixing can these pumps perform?

They can perform in-line mixing, homogenisation, dispersing solids or gases into liquids, pulping bulky solids, and producing stable emulsions or suspensions.

6. Can the pumps be used for continuous production?

Absolutely. Both the SFP2 and SFP3 are suitable for continuous in-line processing, while the CM allows precise control over particle size and high-shear mixing in continuous or batch operations.

7. How easy is maintenance?

Packo pumps are robust and designed for low maintenance, with standardized components for easy spare parts replacement and minimal downtime.

8. Can the CM adjust particle size?

Yes. The adjustable rotor–stator gap allows precise control of particle size, ensuring consistent and reproducible results for different products.

9. Where do you deliver and what are your estimated shipping times?

The team at Global Pumps understand how important it is for you to receive your order as quickly as possible. That’s why we strive to provide speedy delivery to your door, no matter where you are located across Australia.

| Locations |

Shipping Time Range |

| Melbourne |

1-2 Days |

| Sydney |

2-3 Days |

| Brisbane |

2-4 Days |

| Perth |

2-4 Days |

| Adelaide |

1 Day |

| Kalgoorlie |

3-5 Days |

| Mt Isa |

3-5 Days |