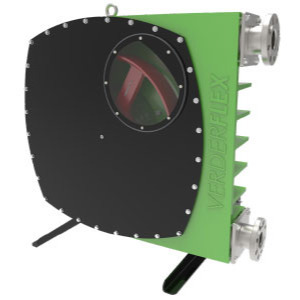

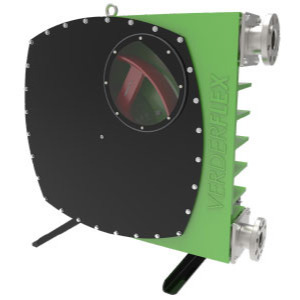

Peristaltic Dosing Pumps

Our peristaltic dosing pumps are ideal for demanding chemical applications. Instead of valves or seals, they use flexible hoses or tubing compressed by rollers to deliver fluids precisely and reliably.

Peristaltic dosing pump key characteristics

- Handles high-viscosity and abrasive fluids – including slurries, polymers, and flocculants.

- Dry-running capability – operates safely without fluid.

- Accurate and repeatable dosing – ensures precise chemical control.

- Gentle pumping action – suitable for shear-sensitive chemicals and food-grade dosing pumps.

- Reversible flow – easy emptying of hoses or tubing, reducing waste.

- Simple maintenance – only hoses or tubing contact fluid, making part replacement fast and cost-effective.

- Continuous duty operation – reliable for 24/7 processes.

- No valves, seals, or glands – minimises leakage or clogging risks.

- Wide chemical compatibility – handles acids, alkalis, detergents, and more

Dosing pump capacity

The largest model in our peristaltic range, the Verderflex VF125 series, offers impressive capacity:

- Max flow: 90 m³/hr (1,500 L/min)

- Max pressure: 16 bar

- Max solid size: 31.5 mm (soft), 12.5 mm (hard)

For specific details and performance data across the full range, visit our Verderflex peristaltic pump range.

Applications

- Flocculant dosing pumps for water & wastewater treatment.

- Food-grade chemical dosing in beverage or food production.

- Industrial dosing pumps for detergents, polymers, and other chemical processes.

As a trusted dosing pump supplier in Australia, Global Pumps also provides hoses, tubing, spare parts, and accessories to ensure long-term reliable performance.

.webp?width=383&height=300&name=Verderflex-Vantage-5000%20Peristal%20(1).webp)

.webp)